Install the first single-sided friction plate with inside splines. Install the first single-sided friction plate with outside splines. (That means when the pressure plate is in the drum you can see the groove when looking down inside the drum).5. Install the grooved pressure plate with the groove facing up. Use only the 3-4 apply ring with the number 7 stamped on it. The 0.120” snap ring will not fit in the snap ring groove.)ĭ. (Identified by the thin snap ring groove. Make sure you are using a 1988 or later input drum.

Note: See Optional Shim Installation Instruction BelowTo properly install the Z Pak™ do the following:Ĭ. Failure to do so may cause incorrect end play reading. If clearance is measured with feeler gauges, it is important to measure in two places at the same time, 180° apart, for even loading of the pressure plate. It is recommended to check actual piston travel by placing a dial indicator on the backing plate and apply air to the third clutch feed. Finally, install the 0.145” pressure plate provided, followed by the factory snap ring.Ĭlearance should be within the 0.050”-0.070” range if not see 6a above. Use of load release springs recommended for RPM above 5000.7. ** Install optional External spline shim to adjust clearance to 0.050” - 0.070” if necessary.Note: Use of load release springs is optional. Using it anywhere else in the pack will damage the clutch pack and void the warranty.Ī. It is critical to install this plate last.

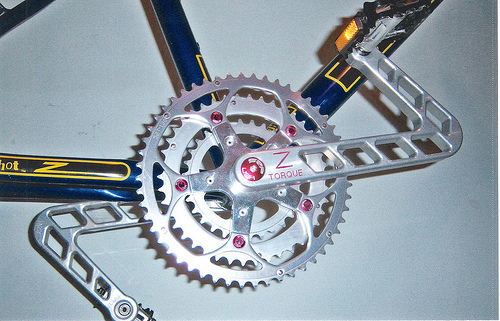

This external spline plate does not look like any of the others. IMPORTANT! Install the special external spline friction plate, identified by the narrow band of friction material, with the word “TOP” facing up. Install the friction plates, beginning with an external spline friction plate with friction material facing upward (away from the special grooved apply plate), then an internal spline friction plate with friction material facing upward, continue alternating until you have installed seven external spline friction plates and seven internal spline friction plates.Ħ. First, install the special grooved apply plate (bottom) with the groove facing upward.Do not attempt to install the narrow external spline friction plate, with “TOP” printed on it, into the machined groove. Pre-soak all friction plates in ATF fluid prior to final assembly.Ĥ. The number “7” is stamped into the part for identification. This stamped steel ring rests on top of the 3-4 piston. Use only a 3-4 apply ring measuring 3.675” ± 0.005” inches tall, commonly referenced as a Number 7 apply ring. Use a 1988 or later input drum, identified by narrow snap ring groove and a 0.093” 3-4 snap ring.Ģ.

0 kommentar(er)

0 kommentar(er)